When it comes to aseptic filling, there are several methods that companies can choose from to ensure product quality and safety. Two common methods of aseptic filling are rotary filling and linear filling. The main difference between these two methods lies in the way containers are filled with the product.

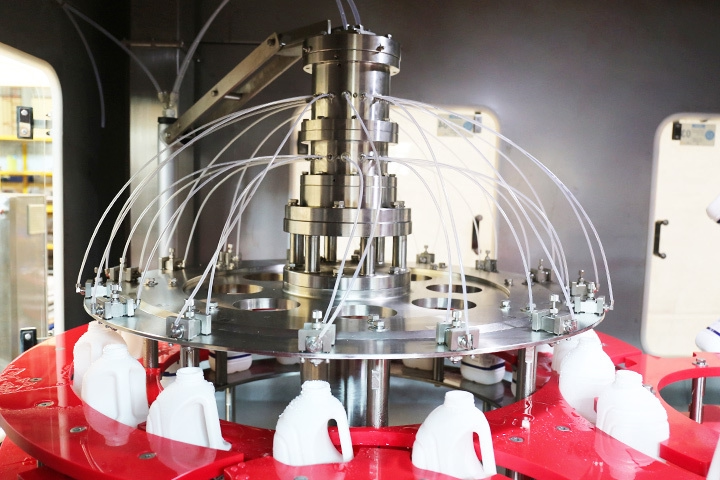

Rotary Filling: High-Speed Production for Small Containers

Rotary filling machines are designed to fill multiple containers simultaneously as they move along a circular path. This method is typically used for high-speed production lines where the containers are small and the products need to be filled quickly. Rotary filling machines are efficient and can handle a large volume of products in a short amount of time. However, they require more maintenance and are not as flexible as linear filling machines.

Linear Filling: Flexibility and Precision for Smaller Production Lines

On the other hand, linear filling machines are designed to fill containers in a straight line, one at a time. This method is often used for smaller production lines or products that require more precision in filling. Linear filling machines are more flexible and can be easily adjusted to accommodate different container sizes and products. While they may not be as fast as rotary filling machines, they are more reliable and easier to maintain.

Gravity Filling: A Simple and Cost-Effective Method

Another important factor to consider when choosing an Aseptic filling machine method is whether to use gravity or pressure to fill the containers. Gravity filling relies on the force of gravity to fill the containers with the product. This method is simple and cost-effective, but it may not be suitable for products with high viscosity or those that require precise filling levels.

Pressure Filling: Fast and Accurate Filling for Specialized Products

Pressure filling, on the other hand, uses compressed air or gas to force the product into the containers. This method is ideal for products that require fast and accurate filling, such as carbonated beverages or pharmaceuticals. Pressure filling machines can easily adjust the filling levels and ensure that each container is filled to the exact specifications. However, pressure filling machines require more maintenance and can be more expensive to operate.

Conclusion: Choosing the Right Aseptic Filling Method

In conclusion, when comparing aseptic filling methods, companies should consider factors such as production speed, flexibility, precision, and cost. Rotary filling machines are best suited for high-speed production lines with a large volume of products, while linear filling machines are more flexible and precise for smaller production lines. Gravity filling is a simple and cost-effective method, but may not be suitable for all products, while pressure filling is ideal for products that require fast and accurate filling. Ultimately, the choice of aseptic filling method will depend on the specific requirements of the product and the production line.