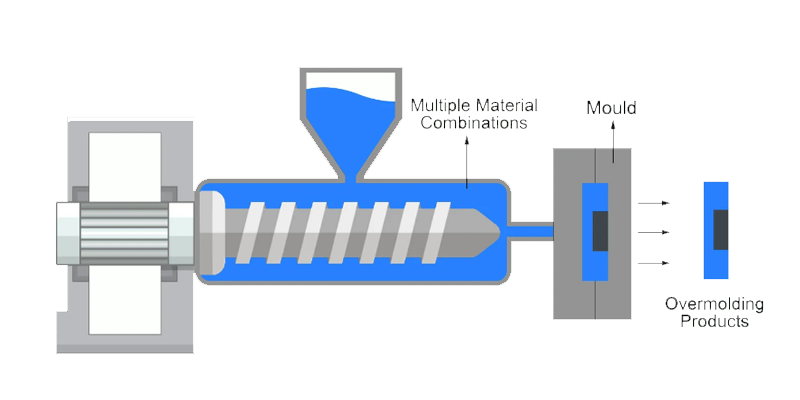

When it comes to manufacturing complex products, insert and overmolding services offer streamlined solutions that can help maximize efficiency and improve the quality of the final product. These specialized processes involve inserting a component, such as an electronic device or a metal part, into a mold and then overmolding it with a protective material, such as plastic, rubber, or silicone.

Complex Designs Made Possible

One of the key advantages of insert and overmolding services is the ability to create products with complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. By allowing for the integration of multiple materials and components in a single mold, insert and overmolding services enable manufacturers to produce intricate, multi-functional products that meet the specific needs of their customers.

Enhanced Durability and Longevity

Another benefit of insert and overmolding services is the increased durability and longevity of the final product. By encapsulating the inserted component with a protective material, manufacturers can significantly enhance its resistance to environmental factors, such as moisture, heat, and impact. This not only improves the overall quality of the product but also extends its lifespan, making it more reliable and cost-effective in the long run.

Reduced Production Costs and Lead Times

In addition to improving the performance and durability of the product, insert and overmolding services can also help manufacturers reduce production costs and lead times. By combining multiple manufacturing processes into a single step, insert and overmolding services can streamline production and eliminate the need for additional assembly and finishing steps. This not only saves time and labor but also reduces the risk of errors and defects, resulting in higher-quality products that are delivered faster and more efficiently.