Ultraviolet (UV) LED modules have become increasingly popular in various industries, including medical, industrial, and commercial applications. These modules utilize light-emitting diodes (LEDs) to produce UV light, which is then used for various purposes such as curing, disinfection, and sterilization. In recent years, there has been a growing demand for compact and lightweight UV LED module that can be easily integrated into various systems and devices. In this article, we will explore the innovations in UV LED module design, highlighting the compact and lightweight solutions that are revolutionizing the industry.

Compact UV LED Module Design

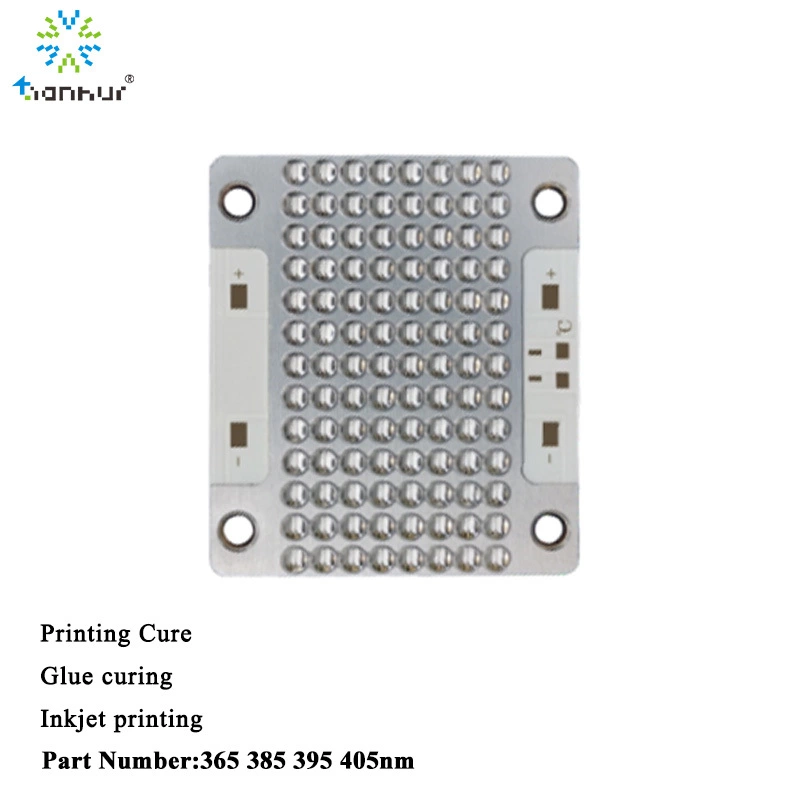

One of the primary innovations in UV LED module design is the development of compact modules. These modules are designed to be smaller and more lightweight than traditional UV LED modules, making them ideal for use in applications where space is limited. Compact UV LED modules are achieved through the use of advanced LED packaging technologies, such as flip-chip and wire-bonding. These technologies enable the LEDs to be mounted directly onto a substrate, reducing the overall size of the module.

Lightweight UV LED Module Design

Another innovation in UV LED module design is the development of lightweight modules. These modules are designed to be lighter and more portable than traditional UV LED modules, making them ideal for use in applications where weight is a concern. Lightweight UV LED modules are achieved through the use of advanced materials and manufacturing techniques, such as 3D printing and laser cutting. These techniques enable the creation of complex geometries and structures that are both strong and lightweight.

Thermal Management in Compact UV LED Modules

One of the key challenges in designing compact UV LED modules is thermal management. As the LEDs are packed more tightly together, the risk of overheating increases. To address this challenge, manufacturers are using advanced thermal management techniques, such as heat sinks and thermal interfaces. These techniques enable the efficient dissipation of heat, ensuring that the LEDs operate within a safe temperature range.

Optical Design in Compact UV LED Modules

Another key challenge in designing compact UV LED modules is optical design. As the LEDs are packed more tightly together, the risk of optical losses increases. To address this challenge, manufacturers are using advanced optical design techniques, such as lens design and beam shaping. These techniques enable the efficient transmission of UV light, ensuring that the module delivers the required intensity and uniformity.

Applications of Compact and Lightweight UV LED Modules

Compact and lightweight UV LED modules have a wide range of applications, including medical devices, industrial automation, and commercial lighting. In medical devices, compact UV LED modules are used for applications such as wound healing and skin treatment. In industrial automation, compact UV LED modules are used for applications such as curing and inspection. In commercial lighting, compact UV LED modules are used for applications such as disinfection and sterilization.

Future Developments and Trends

The future of UV LED module design looks promising, with ongoing research and development aimed at improving the efficiency and effectiveness of these modules. Advances in LED technology are expected to increase the intensity and uniformity of UV light, enabling new applications and uses. Additionally, the development of new materials and manufacturing techniques is expected to enable the creation of even more compact and lightweight UV LED modules.

Conclusion

In conclusion, innovations in UV LED module design have led to the development of compact and lightweight solutions that are revolutionizing the industry. These modules are ideal for use in applications where space and weight are limited, and they offer a range of benefits, including improved efficiency, reduced size, and increased portability. As technology continues to evolve, we can expect to see even more innovative applications of UV LED modules in various industries.