Aseptic filling is a critical process in the pharmaceutical and food industries that ensures products are free from contamination by harmful microorganisms. Understanding the principles, processes, and benefits of aseptic filling is crucial for maintaining product safety and quality.

Principles of Aseptic Filling:

The main principle of aseptic filling is to prevent contamination of products with microorganisms such as bacteria, fungi, and viruses. This is achieved by creating a sterile environment in which the product is filled into sterile containers. The key components of aseptic filling include sterilizing the product, the packaging materials, and the filling equipment, as well as maintaining aseptic conditions throughout the filling process.

Processes of Aseptic Filling:

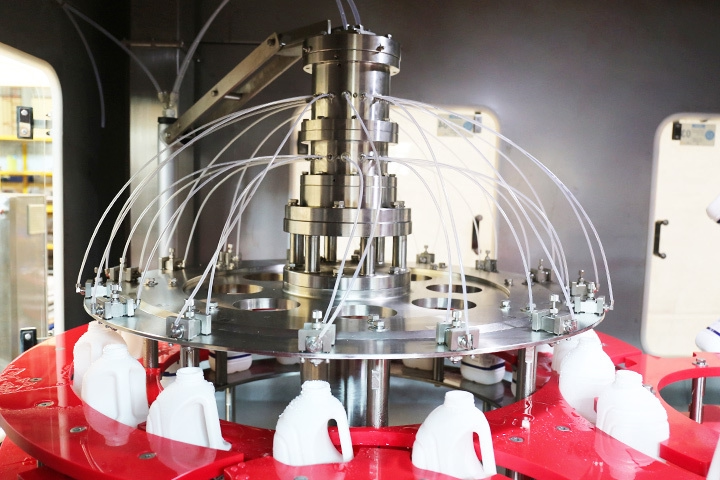

The aseptic filling process can be divided into several key steps. First, the product and packaging materials are sterilized using methods such as steam sterilization, chemical sterilization, or irradiation. The filling equipment is also sterilized to prevent contamination. The product is then filled into the sterile containers in a controlled environment using techniques such as blow-fill-seal, form-fill-seal, or bottling. Finally, the filled containers are sealed and labeled before being shipped for distribution.

Benefits of Aseptic Filling:

There are several benefits to using aseptic filling in the manufacturing of pharmaceuticals and food products. The most significant benefit is the prevention of contamination, which ensures product safety and extends shelf life. Aseptic filling also allows for the use of heat-sensitive ingredients and reduces the need for preservatives, making products healthier for consumers. Furthermore, Aseptic filling machine can increase production efficiency by reducing the risk of batch failures due to contamination.

In addition to these benefits, aseptic filling can also help companies comply with regulatory requirements and maintain a positive reputation with customers. By ensuring that products are free from harmful microorganisms, companies can avoid costly recalls and legal issues. Aseptic filling also allows companies to expand their product lines by offering new formulations and packaging options that require sterile processing.

In conclusion, understanding the principles, processes, and benefits of aseptic filling is essential for companies in the pharmaceutical and food industries. By implementing aseptic filling practices, companies can ensure the safety and quality of their products, reduce production costs, and maintain compliance with regulatory standards. Aseptic filling is a critical component of modern manufacturing processes that can help companies succeed in today’s competitive market.