Insert molding services are a specialized manufacturing process that combines the benefits of injection molding with the added advantage of incorporating pre-fabricated components, such as metal or plastic inserts, into the final product. This process allows for the creation of complex components with improved performance, durability, and functionality. In this article, we will explore why insert molding services are essential for complex parts.

Complexity of Modern Components

Modern components are becoming increasingly complex, with intricate designs and geometries that require precise manufacturing techniques. Insert molding services provide a solution for creating these complex components by allowing for the incorporation of multiple materials and components into a single part. This enables the creation of components with improved performance, durability, and functionality.

Limitations of Traditional Manufacturing Methods

Traditional manufacturing methods, such as machining and casting, have limitations when it comes to creating complex components. These methods can be time-consuming, expensive, and may not be able to produce components with the required level of precision and accuracy. Insert molding services, on the other hand, provide a cost-effective and efficient solution for creating complex components.

Benefits of Insert Molding Services

Insert molding services provide several benefits for complex parts, including improved performance and durability, reduced production costs, and increased efficiency and productivity. The use of insert molding services also enables the creation of components with precise tolerances and geometries, which is critical for many modern applications.

Improved Performance and Durability

Insert molding services enable the creation of components with improved performance and durability by allowing for the incorporation of multiple materials and components into a single part. This enables the creation of components that can withstand the stresses and strains of modern applications, such as high-temperature and high-pressure environments.

Reduced Production Costs

Insert molding services provide a cost-effective solution for creating complex components by reducing the need for secondary operations, such as machining and assembly. This enables manufacturers to reduce production costs and improve efficiency and productivity.

Increased Efficiency and Productivity

Insert molding services enable manufacturers to increase efficiency and productivity by allowing for the creation of complex components in a single operation. This reduces the need for multiple manufacturing steps and enables manufacturers to produce components more quickly and efficiently.

Design Considerations for Insert Molding Services

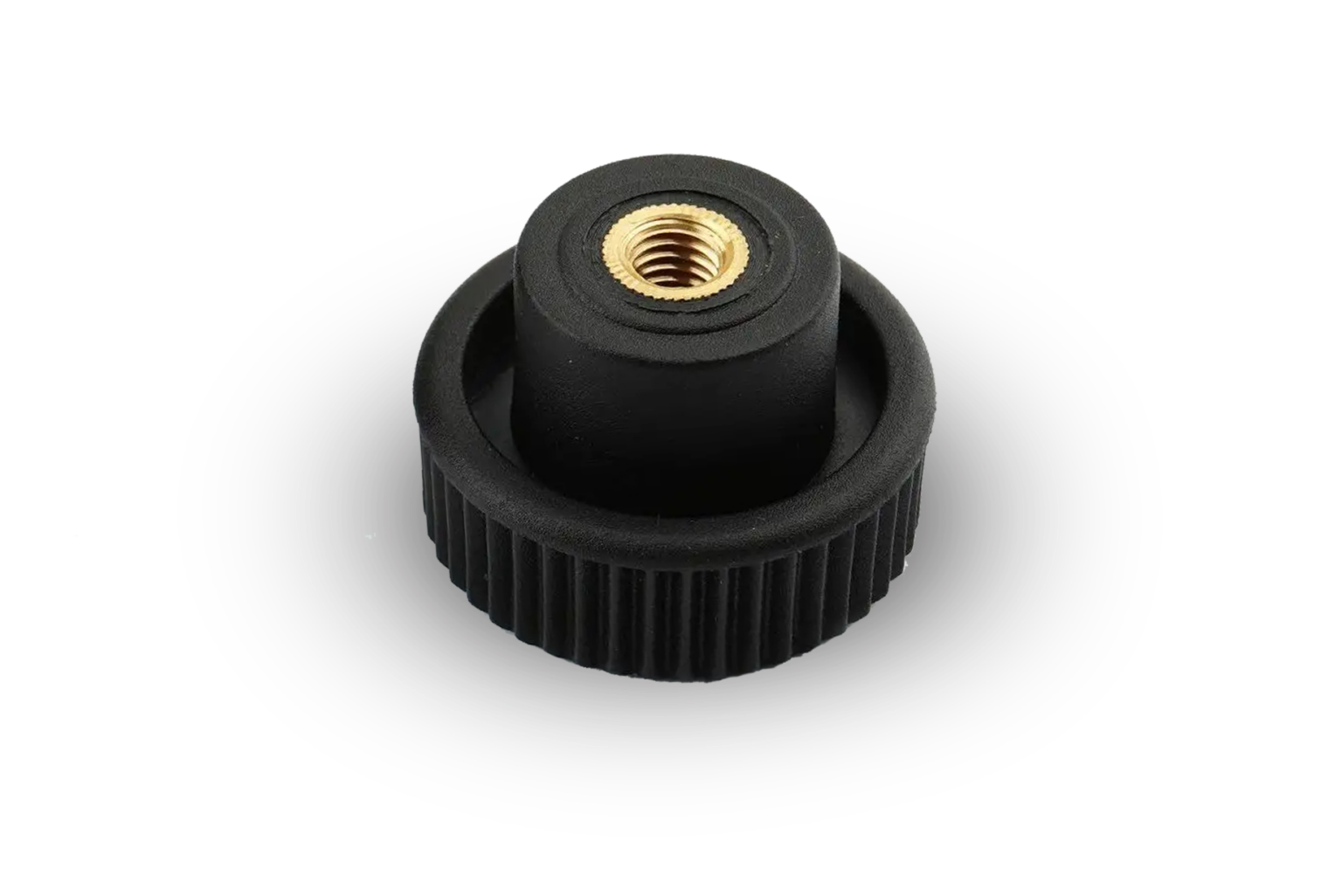

When designing a component for insert molding services, there are several factors to consider, including the type of insert material, the size and shape of the insert, and the desired bond strength between the insert and the plastic material. The type of insert material will depend on the specific application and the desired properties of the final product.

Material Selection for Insert Molding Services

The selection of materials for insert molding services is critical to the success of the project. The insert material must be compatible with the plastic material, and must be able to withstand the stresses and strains of the molding process. Common materials used for insert molding services include metals, such as stainless steel and brass, as well as plastics, such as nylon and polypropylene.

Conclusion

In conclusion, insert molding services are essential for complex parts because they provide a cost-effective and efficient solution for creating components with improved performance, durability, and functionality. By enabling the incorporation of multiple materials and components into a single part, insert molding services enable the creation of components that can withstand the stresses and strains of modern applications.